San Juan is name place that holds a special place in our hearts. The land we call home is surrounded by it, quite literally. There is a San Jaun county to our North, and also to our South. The San Juan River originates high in the eastern San Juans at the Continental Divide, flowing down into Pagosa Springs before emptying into Navajo Lake. The Animas River that is the lifeblood of Durango winds its way south until meeting the San Juan River just on the other side of the New Mexico border and downriver from Navajo Lake. From there, this sacred snowmelt continues it’s journey through ancestral Colorado Plateau lands, carving deep canyons and hiding secrets of a sophisticated culture long gone until meeting up with the mighty Colorado River at Glen Canyon.

Water is only a small part of the equation. Then comes the dirt, rock, minerals, trees, grasses, flowers, and wild creatures that form one of the most majestic mountain ranges in all of North America, the San Juans. Spanning over 13 counties, with 13 peaks over 14,000′, 314 peaks over 13,000′, and hundreds more over 12,000′, the San Juans are not only the largest and tallest range in Colorado, but also considered by many to be the prettiest, the most rugged, the most isolated, and the most majestic. Having lived here over 10 years, I have explored my fair share of this pristine land, but feel like I have just touched the tip of the iceberg. I’m always blown away at the awesomeness of this place I get to call home.

I have saved this name for the right build ever since opening shop back in early 2013. Reserving the name “San Juan” for one of our tiny builds was no light task. How do you design and build a house that can embody such a magnificent landscape? In the end, I don’t really think you can. But I do think you can make an honest attempt. I present to you the San Juan Tiny House.

Prelude

For starters, this is my new personal tiny house, shared with my amazing wife Stephanie, and our two furballs ,Rocco and Jade. We were living in the 16′ Durango model that I first built in Spring of 2013, and although it met basic living needs and was dirt cheap for our first two years together, it was just a little cramped for that many occupants. We knew at some point we would design and build a larger tiny house. In between build #1 and #62, we learned a thing or two about tiny house design, and attempted to integrate as many of these lessons into the design goals as possible.

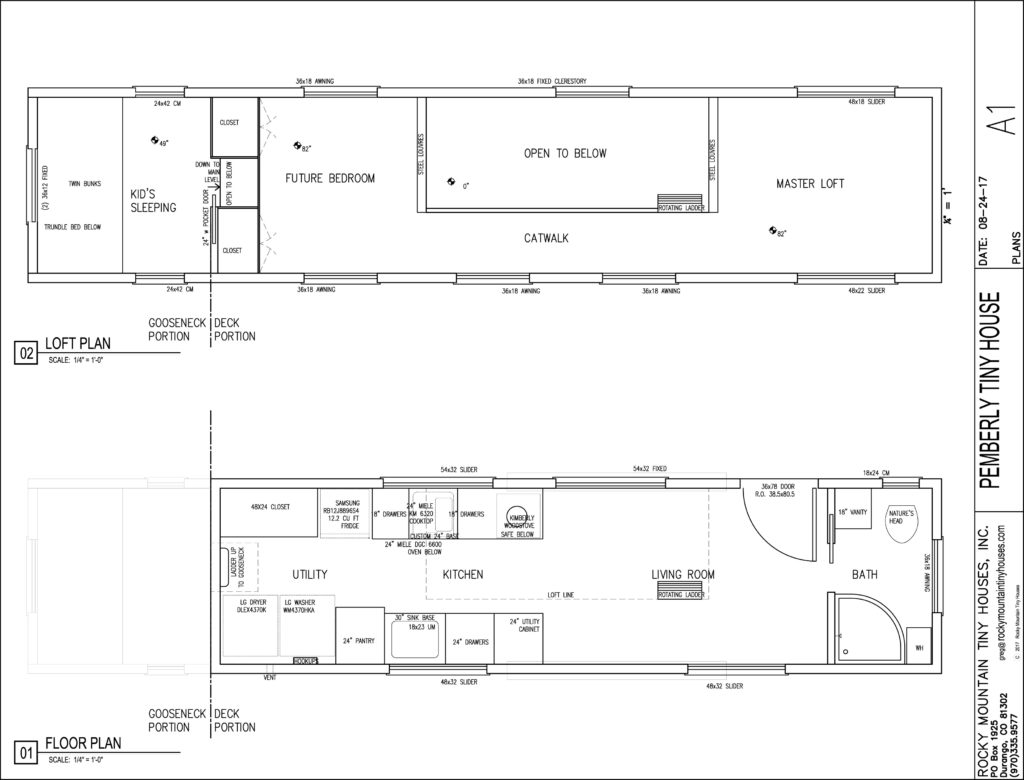

The design phase lasted over a year before we were able to secure enough funds to start the build. The build phase then took another year. When you run a tiny house construction company, it proves quite difficult to build a house for yourself! In addition to being our personal living quarters, I knew it would be a great model house to take to shows, so some of the decisions (which added a lot of build time, and a little bit of civil unrest) were also influenced by this. So far the San Juan has attended 4 tiny house festivals across the US traveling a total of more than 5,000 miles!

The design phase lasted over a year before we were able to secure enough funds to start the build. The build phase then took another year. When you run a tiny house construction company, it proves quite difficult to build a house for yourself! In addition to being our personal living quarters, I knew it would be a great model house to take to shows, so some of the decisions (which added a lot of build time, and a little bit of civil unrest) were also influenced by this. So far the San Juan has attended 4 tiny house festivals across the US traveling a total of more than 5,000 miles!

We actually started the build as a SIP workshop at the inaugural Colorado Tiny House Festival in 2017, an event of which RMTH helped organize. With the help of a few crew members and curious strangers, we got the walls erected in a day and a half. The shell made the trip back to Durango where Stephanie and I completed about 99% remaining work on nights and weekends.

We actually started the build as a SIP workshop at the inaugural Colorado Tiny House Festival in 2017, an event of which RMTH helped organize. With the help of a few crew members and curious strangers, we got the walls erected in a day and a half. The shell made the trip back to Durango where Stephanie and I completed about 99% remaining work on nights and weekends.

Structure

Trailer Made Trailers helped us out with this custom 8′-4″ wide vee nose chassis. 24′ is the max you can go with tandem axles, and we really did not want another 36″ of fender protruding into the space, but 24′ was slightly small for our design goals, so we cheated with the 30 degree vee nose. We cheated even more by angling the walls up another 15 degrees. The end result is akin to the bow of a ship, although our intentions were strictly trying to get more space! This unique shape did indeed give us more space for a limited footprint, however I will point out that it added substantially to the tongue weight. I knew it would and asked Trailer Made to slide the axles forward a little, which they did, but without listing the tongue weight here, I will say you are definitely in Dually territory, and will need to also use weight distribution! If we did it again, I would slide the axles forward even more, or would just not cheat and go with three axles! It really is more like a 26′ long house. The ridge beam is 29′ at the longest part of the house!

For the roof shape, we took some cues from the beloved Pequod build, but flattened the curves out some to make roof and ceiling installation easier. Its always a little trial and error when working with shapes like this, but the metal roof did go on without any awkward seams, and for the locally sourced/milled Aspen shiplap on the ceiling, we did not have to reverse direction of the boards to get them to conform. It worked out very nicely! SIP’s cannot be warped into a spherical aspect, so just like on the Pequod, we had to stick frame the roof.

The complex angles and curves were all figured out using 3d modeling software, which we were able to provide to Porter SIP’s, at which point their automation software was able to precisely CNC cut all of the SIP wall panels, sparing us the cruelty of having to figure out this crazy shape with stick framing!

Exterior

We decided to go with as much reclaimed material as possible, mostly because I had a ton of such material already laying around at the shop! We work with reclaimed corrugated and barnwood all the time, so these two were a no brainer. The tin makes up a 36″ wainscot on the front, driver side, and most of the passenger side. On the driver side, we then added a row of barnwood to match window heights, and stained cedar shakes leftover from old projects up above. On the passenger wall, we had a big blank section without any fenestration, so we decided to spruce it up using porthole windows radially aligned with the roof, and continued this radial pattern with sun rays made from the biggest planks of barnwood that I had left sitting on my shelves.

For the rear wall, I had a few bundles of pre-primed cedar shakes leftover from a contractor sale a few years back, so we thought an ombre pattern with seven shades of blue to mimic the changing Colorado horizon would be cool here. We gave the fascia and doghouse window trim some styled lines for a little distinction over straight boards.

For the front wall, I had a lot of culled lap cedar boards sitting on the rack. I ran them through the planer to flatten out the bevel and straighten them out. I then installed vertical as board and batt.

We splurged on top of the line Kolbe VistaLuxe windows for their clean, minimal lines, choice of color on the exterior metal cladding, and warm Alder wood on the inside. It was probably the most expensive line item on our cost sheet, but no regrets!

Kitchen/Dining

The centerpiece of our kitchen is a deep 24″ wide composite granite apron sink. Surrounding the sink is a custom live edge counter made from south Texas black mesquite, inlayed with Sleeping Beauty Turquoise from Arizona. To the left of the sink is our dining area. With some very careful detail work, I was able to create a slot for a floating butcher block table to slide in and out of. No hardware whatsover. It just floats, and with help from a little beeswax slides around very easily. We have it fully extended for dining mode for up to three, halfway in for laptop mode, or all the way in when we want to free up some space in the living room.

The base cabinet to the right of the sink serves as our pull out trash and recycling center. Next to this is a 24″ white gas range. We had to look long and hard for a white 24″ range hood with clean lines that did not break the bank! Anchoring the hood is an angled cupboard where we store most of our dishware. There is one more base cabinet next to this topped with a Silestone counter. Steph wanted an indestructible surface for cooking and cleaning functions that would not be affected by heat, acid, scratching, etc. There is a glue up shelf stretching from the hood cupboard all the way across our massive 6′ wide window into the dining area. This has multiple functions as plate holder, Scotch and Tequila (our favs) shelf, decorations, and coffee supplies!

On the other side of the galley kitchen, a Kimberley woodstove provides primary heat for our chilly Colorado winters. Using Portuguese tile and a decorative metal grate, we separate the stove from the 10 cu ft LG refrigerator with bottom freezer. This model has come to be our absolute favorite tiny house fridge! Next to the fridge is a double pull out pantry for dry food storage.

The cabinets were all built in house to accommodate the custom features and functions we desired.

Bathroom

This is where the vee nose and sloped walls really allowed us to maximize space over a square and plumb endwall. Featuring a freestanding tub with a floor mount faucet, live edge counter with vessel sink made from a brass enameled bowl, a one of kind antique dragon faucet Stephanie found on Etsy, a simple but functional Nature’s Head toilet, an antique medicine cabinet, very large built in linen closet, 100 gallon freshwater tank integrated into the wall, and little built in cubbies to the side of the tank, this bathroom has everything you need and then some! Oh, and did we mention it has a penny floor!? It took Steph 3 days to lay the $80 worth of pennies and another two to pour the epoxy, but it turned out amazing! Another notable feature in this space is the Islandia glass tile in a Chevron pattern making up the backsplash.

Storage

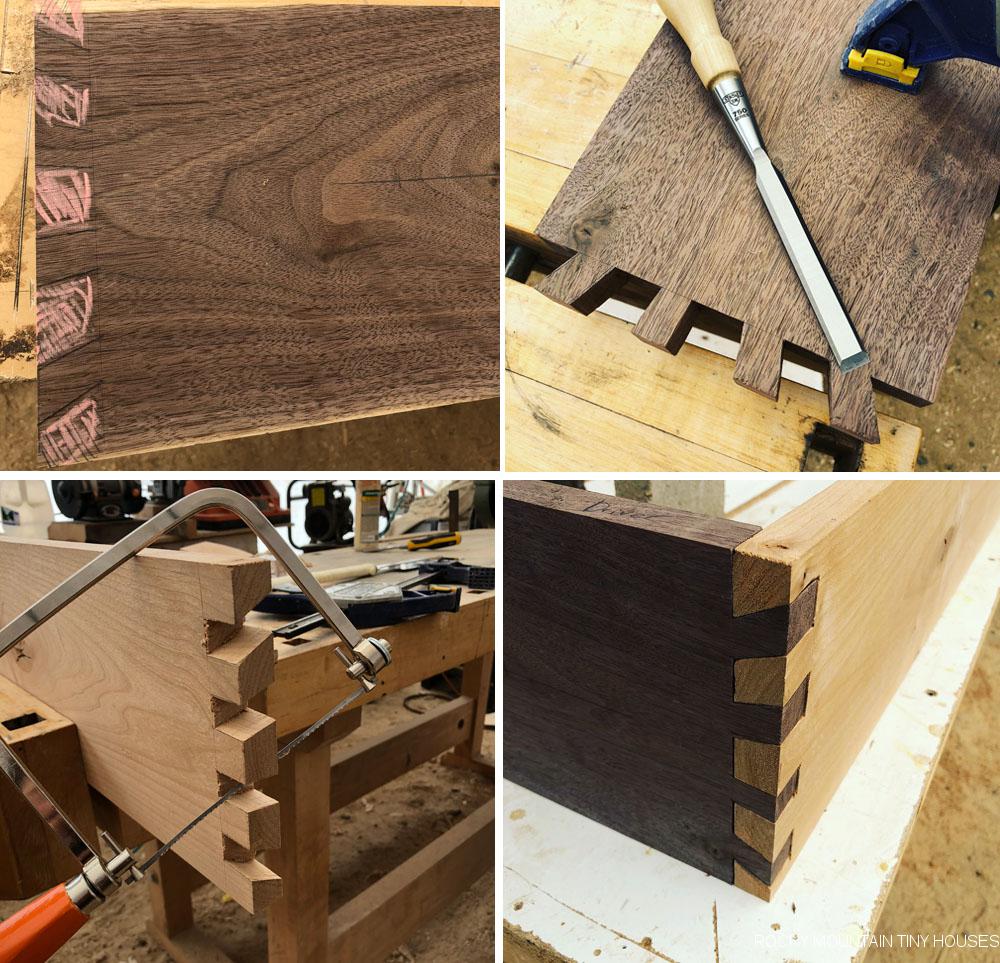

The bathroom is separated from the kitchen by our closet area. Greg gets a full height closet that is shared with utility components. On the opposite side, Steph has a half height wardrobe for hanging items. Below this is ten drawers-five for each person- for socks, underwear, shorts, cycling gear, etc. These drawers were crafted in the old style with dovetails, inlays, and waxed wood slides instead of ball bearing slides. This saved a little money and space, but there is also just enough friction to keep them from sliding out when traveling.

Because the entry door is over the wheel well, this required a platform for safe entry/egress. We stretched this platform all the way to the pull out pantry, providing enough width for 5 drawers which are all used for long term shoes storage. We planned for short term shoe storage under the overhang of the tiled woodstove hearth. Underneath the hearth is plenty of room for firewood storage.

The built in bench for the dining table has a flip top seat where we store dog food. There is a long shallow space behind the angled couch that is perfect for our hunting rifle storage. The couch also has an arm rest with a flip top for laptop storage. We left the bottom side of the couch open cubbies to store dog beds and rubbermaids. We have a store bought ottoman to accompany the couch that also has a flip top for misc items. The kitchen base cabinets all have toekick drawers to really squeeze out some extra inches of useable space. There are some hidden compartments tucked away in secret spots, but we aren’t going to tell you where!

Living/Sleeping

After climbing a ladder and sleeping in a cramped space for years, we were over it. We wanted a downstairs sleeping arrangement that did not require stairs or a ladder. We settled on the elevator bed as the perfect solution! Unlike the original Ana White design, we did not want it motorized, nor did we want tracks taking up wall space. After untold hours of research for the right hardware to pull this off, I finally stumbled upon garage door components. I could easily source axles, bearings, cables, cable drums, and a geared down chain hoist. It took some time to fabricate the brackets and get it all together, but the system works quite well! The exposed parts add a little steampunk flair to the interior décor!

We fashioned a custom frame big enough for a queen mattress. The side rails are made from Walnut and Alder joined with hand cut sunrise dovetails. Since the bottom of the bed frame doubles as the ceiling above the living room when the bed is raised, we wanted to look at something nice instead of plywood and lumber. We came up with a southwest mosaic using painted and stained pieces of birch plywood that we attached to the underside of the frame. It is a work of art that we never get tired of looking at!

When the bed is raised during the day, the space below functions as our living room. The built in couch rests along the rear wall and under the 48″ circle window I made in house because I couldn’t swallow the cost of the quotes we were getting to have this ordered from the Vistaluxe line! Same with the pentagon “doghouse” window up high.

Our flooring on the main level, except for the bathroom, is reclaimed elm that was milled into t&g from very old barn beams. We did a herringbone pattern on top of the entry platform to give it some pizzaz and welcoming warmth.

Loft

Even though we don’t sleep up here, it’s still a magical and useful space. The primary function of this area is gear storage. We are your typical Colorado couple engaging in cycling, hiking backpacking, river sports, snow sports, hunting, you name it. We needed a place to store all this gear, so there are adjustable cubbies for this purpose. The secondary use for this space is guest sleeping. There is enough room in the middle for a twin size mattress. The tertiary function of this space is just a cool hangout niche. It’s a real cozy spot to read a book, or serve as a man cave when we need a little space from each other in such tight quarters. Steph has to wake up earlier than I do for work, which means I often stay up later watching Netflix or working, so this gives me a cool place to do this. With the shape of the roof, the porthole windows, wall sconces, and material palette, it is hard to describe the feeling you get when occupying this space… The loft is accessed via a metal telescoping ladder we bought on Amazon. It stores out of the way above the fridge when not needed.

Systems

This house was designed to be fully off grid since we had no idea where it would eventually end up. There are two 360 Watt solar panels fixed to the house that double as our porch awning. The back 12′ of the house has a 3 1/2″ recessed pocket on the passenger side that the awning and aluminum deck fold into for travel. This way they don’t stick out past out 8′-6″ width limitation.

There are four more 360 watt panels ground mounted away from the house for maximum insolation. Wires for all these panels get routed into Greg’s closet where the charge controller and inverter live. There are also four massive AGM batteries rated at 400Ah each. There is room in the system to add either wind or hydro generators, but for now all these components are proving to be adequate.

We did install a mini split for those few weeks in the summer that are uncomfortably warm, and as backup heat on a thermostat in the winter. Because we are running on solar, we made our capacity a little larger and also shopped around for the most efficient mini split on the market. We found it in the GREE Sapphire. It is so efficient it is literally off the charts! Looking at the energy star sticker, models in the class range from 12-30 SEER, and this one is rated at 38 SEER!! It also has the highest heating efficiency on the market at 15 HSPF. It can also heat down to -22F! (I think -10 is about the coldest I have ever experienced in Durango) The tradeoff for this efficiency is that it only comes in 220v operation. This required us to buy a more expensive inverter with 220v output, but sometimes you have to spend a little money up front to save it down the line.

For water, we have a 100 gallon water tank that is sort of hidden in plain sight in the bathroom. You don’t really notice it since it is partly placed in wall thickness, but also it is inside a decorative cage with a Chevron motif that matches the rest of the bathroom. A shurflo pump with accumulator push water through a whole house filter before entering the main plumbing lines.

The water heater and range run on propane to minimize electric load. And of course, we have a nice woodstove for primary heat to reduce the load on the mini split.

We found an antique Westinghouse desk fan that I was able to convert into a ceiling fan, centered above the entry. The oscillator still works, and this thing can move some air! A Lunos eGO kicks out stale, moist indoor air and provides us with fresh outdoor air, while recovering most of the heat energy from inside.

Details

We wouldn’t be doing this house full justice without touching on small details not mentioned thus far. Please enjoy the photo essay at the end to learn more. I could literally spend days talking about all of them, but I will let the pictures do the talking instead!

For the final question on everyone’s mind, how much did it cost? Well, we did not track our hours, so we’ll never know how much retail for such a house would have been, but we can tell you that we spent nearly $55k in materials alone, and this is factoring in several discounts from our suppliers and utilizing a lot of material we acquired for next to nothing. Factor in labor/overhead/profit and the final price would be over 100k. Our goal was not to sell this model, but create something beautiful to meet our living needs and reflect our unique personalities, and also to a degree, showcase the level of craftsmanship and creativity that RMTH as a company is capable of.

Video

At this point, so many people have filmed this house that we have lost track of all the social media links. Don’t worry, we kept the best ones! The Tiny Home Tours version is a bit lengthy, but very informative. If you took any video and would like to share, feel free to send us links!

Shout Outs!

This project was a team effort and could not have been a success without the help of many friends. We’d like to thank:

The entire crew at RMTH for being able to bounce ideas off of, dealing with my projects taking up tools and shop space, and even lending a hand in some of the finished product.

Trailer Made for working with us on the custom trailer foundation

Element Window + Door of Durango, for giving us a great deal on the Kolbe Windows!

A Tiny Good Thing for hooking us up with a Lunos eGO and high quality housewrap and tapes!

Durango Glass for being able to provide the crazy shapes of insulated glass for the rear windows and French Doors

Dave and Jan Masse for getting super involved with the SIP raising at the festival!

John Lesage of LS3 Aerial for providing awesome aerial footage!

Tiny Home Tours and Tiny House Expedition for their sweet videos!

Rocco and Jade dogs for providing moral support and quality control!

And now for the final photo essay! Steph and I have really enjoyed sharing our little slice of heaven with you. A lot of blood, sweat, beers (+tequila), and tears were sacrificed for this build. We hope you have enjoyed learning more about it!