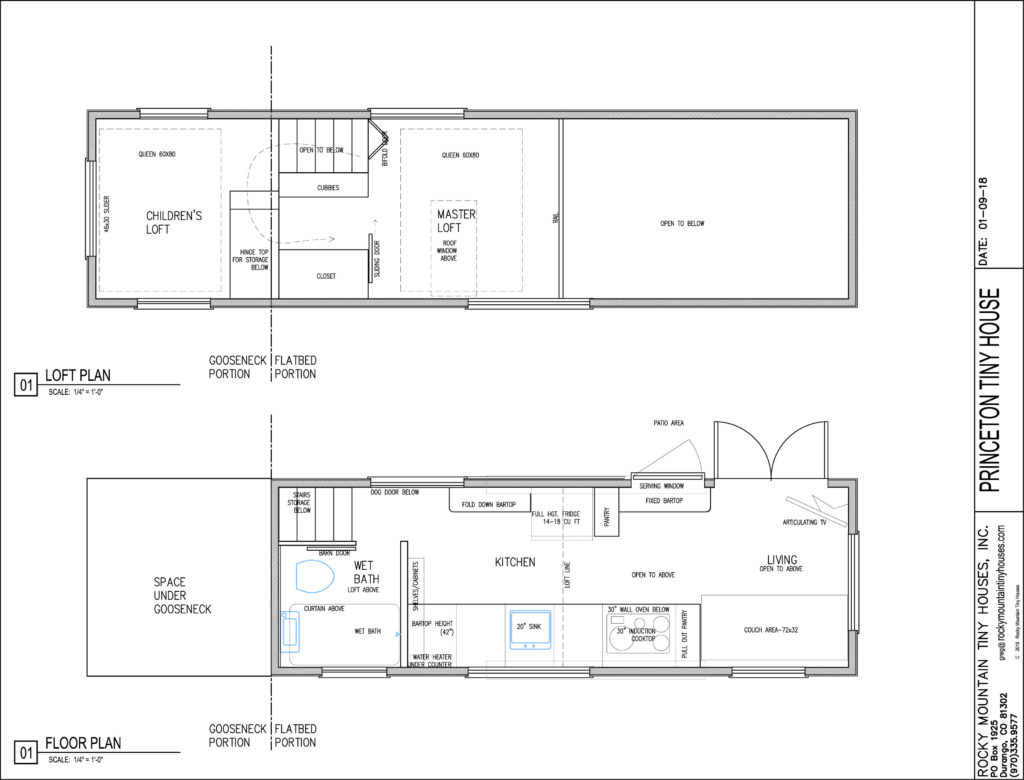

Some nice folks who we met at the 2016 Jamboree hired us to build this unique shell for them. They liked aspects of the Rio Grande build along with some of our other houses, so after brainstorming a few design ideas, we came up with this one. Not only were they on a tight budget, but they were excited to do the finish out work themselves. This shell build consisted of a stick frame structure on a 24+7 triple axle gooseneck trailer and included a fully finished exterior with a French entry door, doggie door, windows, siding, metal roofing, and a roof window (operable skylight) above the master loft. We installed rough wiring and plumbing (including a tankless water heater) prior to spray foaming the studs. Final scope of work included installing the master sleeping loft, tiling the spacious wet bath with some very high end tile, and putting up interior wall/ceiling paneling. Due to an unfortunate tech glitch, we lost photos of the interior, but have attached some plans below. A similar build would be in the 51k range.

We are excited to announce the completion of our first 10′ wide tiny house build! Since permits to move a structure between 8′-6″ and 11′ to 14′ (depending on route) normally only cost $25 per state, we have seen a growing interest to have that extra 2′ width incorporated into designs, especially if the owner doesn’t plan on moving the tiny house very often.

We are excited to announce the completion of our first 10′ wide tiny house build! Since permits to move a structure between 8′-6″ and 11′ to 14′ (depending on route) normally only cost $25 per state, we have seen a growing interest to have that extra 2′ width incorporated into designs, especially if the owner doesn’t plan on moving the tiny house very often.